I. Composition of the Air Conditioning System & Introduction to Components

Composition of the Air Conditioning System:

Automotive air conditioning systems typically comprise the following components: compressor, condenser, receiver-drier, expansion valve, evaporator, blower fan, throttle valve, and ventilation system.

Introduction to Air Conditioning System Components—HVAC Air Conditioning Assembly:

The air conditioning unit employs mode selection dampers to direct cold or warm airflow to specific vents, such as footwell, face, or defrost outlets. Temperature control dampers blend cold and warm air to achieve the desired outlet temperature. The internal/external air mix damper regulates the proportion of cabin and external air, directly influencing temperature, air quality, and defrosting/demisting functionality.

Introduction to Air Conditioning System Components—Condenser:

Function of the condenser: to cool the refrigerant.

The condenser integrated with a dryer, wherein a liquid receiver dryer is installed at the end of the refrigerant circuit within the condenser, facilitates simplified air conditioning system design and enhances the reliability of the refrigeration system.

Introduction to Air Conditioning System Components—Compressor:

The compressor serves as the ‘heart’ of the air conditioning system, analogous to the engine's role in a vehicle—it is the driving unit.

In conventional air conditioning systems, the compressor is driven via an engine belt.

The compressor must exclusively draw in and expel gaseous refrigerant.

Its internal mechanism contains numerous moving parts, necessitating sufficient lubricating oil to lubricate these components.

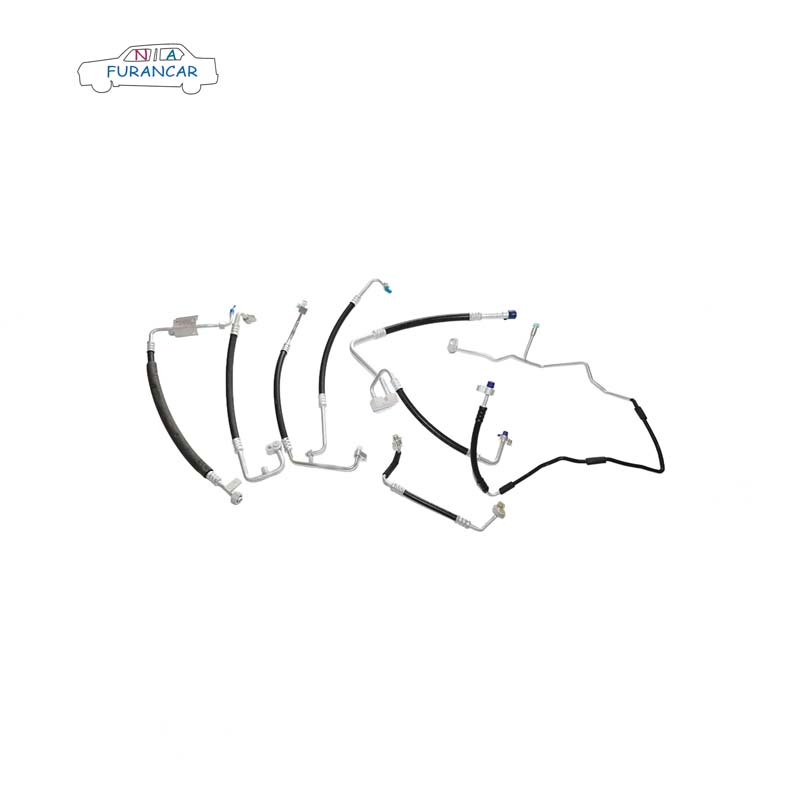

Introduction to Air Conditioning System Components—Air Conditioning Piping:

The air conditioning piping system comprises key components such as aluminium tubing, flexible hoses, and pipe fittings, which collectively connect all elements of the air conditioning system. Aluminium tubing and flexible hoses are tightly joined via crimping techniques, though minor variations in crimp dimensions may exist between different models and manufacturers. To mitigate potential damage from engine vibration, flexible rubber hoses are employed for the lines connecting the compressor's suction and discharge ports. Their flexible design effectively absorbs vibrations, enhances system sealing integrity, and extends the service life of the piping. Many manufacturers have also developed nylon air conditioning hoses, which are utilised in mass-produced vehicle models.

II. Refrigeration Principles of Air Conditioning Systems

The operational principle of refrigeration systems relies upon the continuous vaporisation and liquefaction of refrigerant. The entire refrigeration cycle comprises four distinct operational stages: compression, condensation and heat release, throttling, and evaporation. During compression, the low-temperature, low-pressure refrigerant gas processed by the evaporator is compressed by the compressor into a high-temperature, high-pressure gas, which is then delivered to the condenser. During the condensation and heat release stage, the high-temperature, high-pressure refrigerant gas gradually condenses into a liquid while releasing heat. The subsequent throttling process, via the expansion valve, transforms the refrigerant from a high-pressure to a low-pressure state. Finally, the evaporation process occurs within the evaporator, where the refrigerant absorbs a significant amount of heat before re-entering the compressor, thereby achieving the cooling of the vehicle's interior.

III. Precautions for Air Conditioning Refrigerant Pipe Assembly

When installing air conditioning pipework and connecting components, the method of fitting and tightening joints is critical.

When removing pipe plugs, first inspect the O-ring for integrity and apply lubricant evenly to its sealing surface. For threaded pipe joints, also apply lubricant evenly to the external threads. When applying lubricant, observe the following points:

The lubricant applied must be compressor-grade lubricant, PAG or equivalent grade.

Lubricate threaded sections to prevent seizing after tightening.

To prevent moisture absorption, promptly reseal lubricant containers after use.

To maintain internal cleanliness of system components such as piping, remove plugs only immediately prior to installation. Refit promptly; do not leave exposed to air for extended periods.

Clamp-type joint connection: Insert the lubricated clamp plate's blind hole vertically through the double-ended stud. Simultaneously insert the clamp joint vertically into the corresponding mounting hole. Avoid tilting during insertion to prevent O-ring damage. Once seated with parallel faces, hand-tighten the nut until resistance is encountered. Subsequently, use a torque ratchet or wrench to tighten the bolt to specification, marking the tightened position. The tightening torque for M8 nuts is 15–20 N·m; for expansion valve nuts (M6), it is 6–10 N·m.

Threaded joint connection. Insert the lubricated sealing ring end into the threaded joint end. Align and insert vertically until the front face of the plug head contacts the threaded joint. Hand-tighten the nut, then secure the threaded joint end with an open-end spanner. Tighten the nut end using a torque wrench, marking the tightened position (see figure below). Tightening torque specifications: High-pressure pipe fitting (M16×1.5 threaded joint): 12–15 N·m Low-pressure pipe fitting (M24×1.5 threaded joint): 30–35 N·m.

Note: When tightening threaded joints, it is essential to use two spanners simultaneously to avoid deformation of the pipework.

Connection of dual clamp joints. First position the end of the high-pressure clamp within the fork slot of the low-pressure clamp. Align and push the compressor interface in parallel. Once the clamps are flattened, inspect the O-ring position for misalignment or extrusion. Hand-tighten the bolts until resistance is encountered, then use a torque ratchet or wrench to tighten to specification, marking the tightened position (see figure below). The tightening torque for the compressor tail bolts (M10×1.25×35) is 20–30 N·m.

Supplementary Notes on Air Conditioning Pipe Installation:

Minor damage to O-rings during pipe installation may compromise sealing integrity, leading to refrigerant leakage.

Following installation, verify that pipes do not interfere with or exhibit free movement relative to surrounding vehicle components. Address any friction or interference promptly through adjustment, and secure pipes prone to free movement with appropriate fastenings.

Moving components such as the engine throttle cable and oil dipstick must never be bundled together with air conditioning piping. This prevents abrasion of the air conditioning lines, which could lead to refrigerant leakage.